PHOTO

Specification

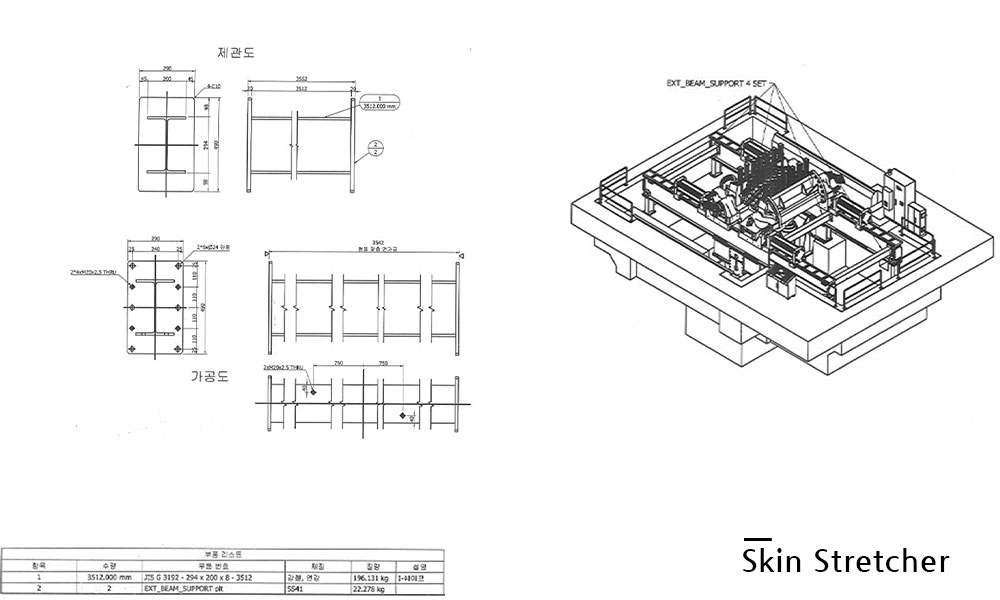

| NO | Equipment name | Workspace(mm) | Equipment Dimension(mm) | Basic Specification | |||||

|---|---|---|---|---|---|---|---|---|---|

| X | Y | Z | Φ | X | Y | Z | |||

| 1 | Skin Stretch Former | 2438 | 3660 | 3.2 | - | 8500 | 3100 | 5000 | Force / DIE TABLE 500TON |

| TENSION 400TON | |||||||||

| WORK PRESSURE 210 BAR | |||||||||

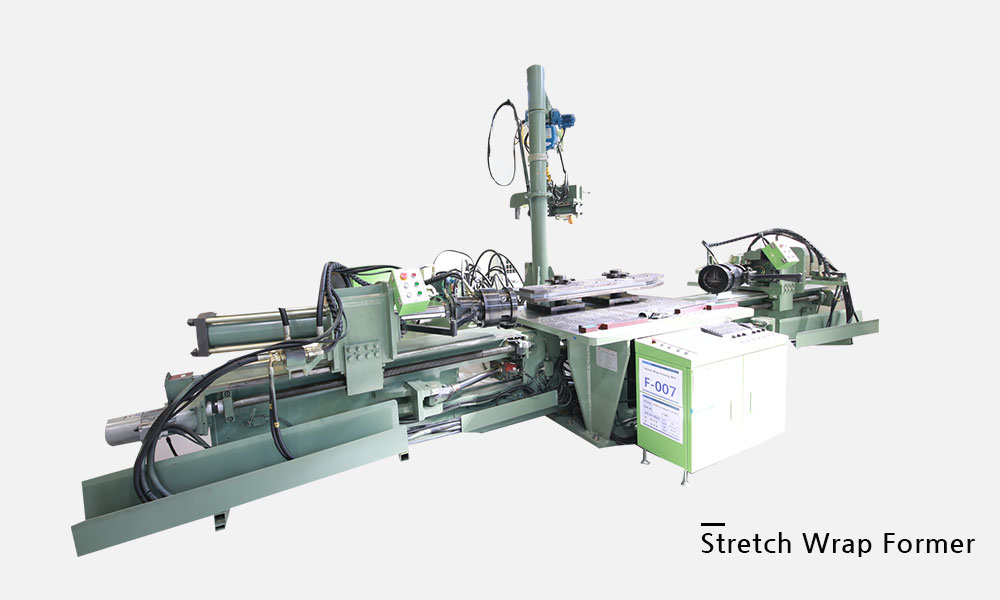

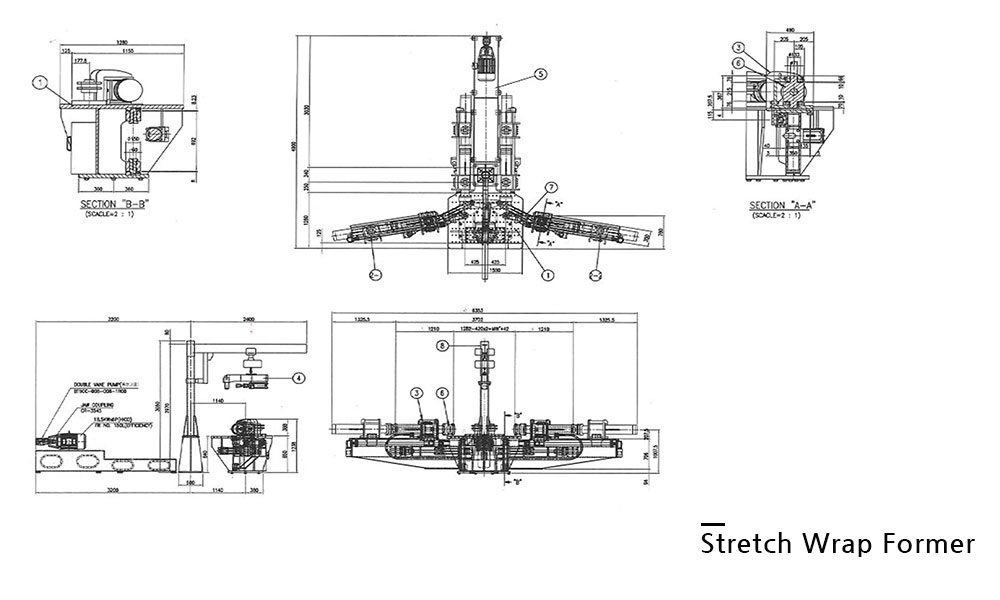

| 2 | Stretch Wrap Former | Forming Possible Length 3300 | 4900 | 6353 | - | ARM 20 TON | |||

| TENSION 30 TON | |||||||||

| WORK PRESSURE MAX.200 BAR | |||||||||

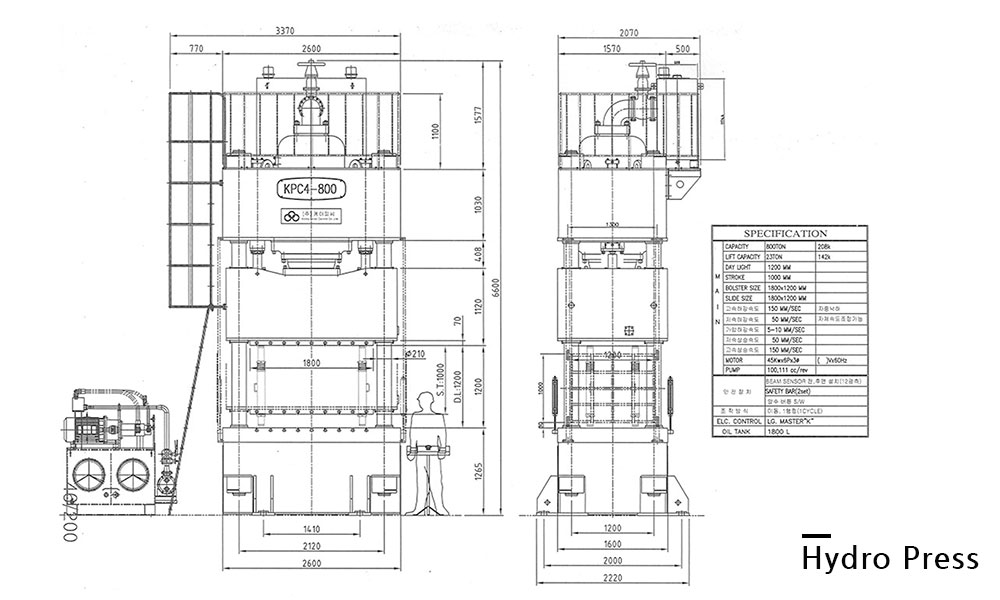

| 3 | Hydro Press | 1200 | 1800 | - | - | 1570 | 2070 | 6600 | Press 800TON |

| Fast rising and falling speed 150MM / SEC, slow rising and falling speed 50MM / SEC |

|||||||||

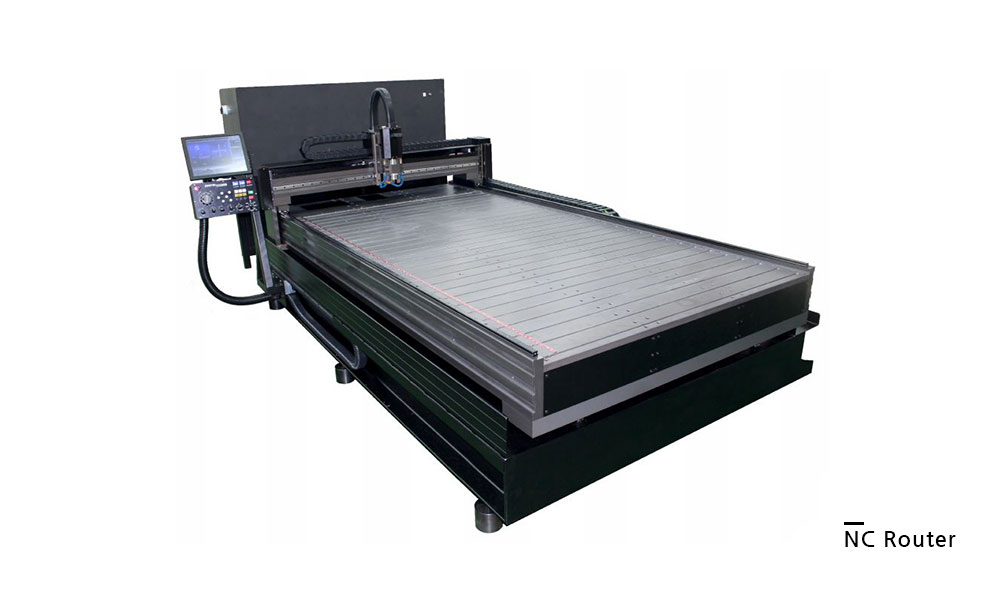

| 4 | NC Router | 1220 | 2440 | 150 | - | 1500 | 3000 | 1200 | Basic functionality with high-speed machining (G61.1) |

| Sliding Capable Removable Control Panel | |||||||||

| 30,000RPM ER11 spindle | |||||||||

| 24,000RPM ER11 spindle | |||||||||

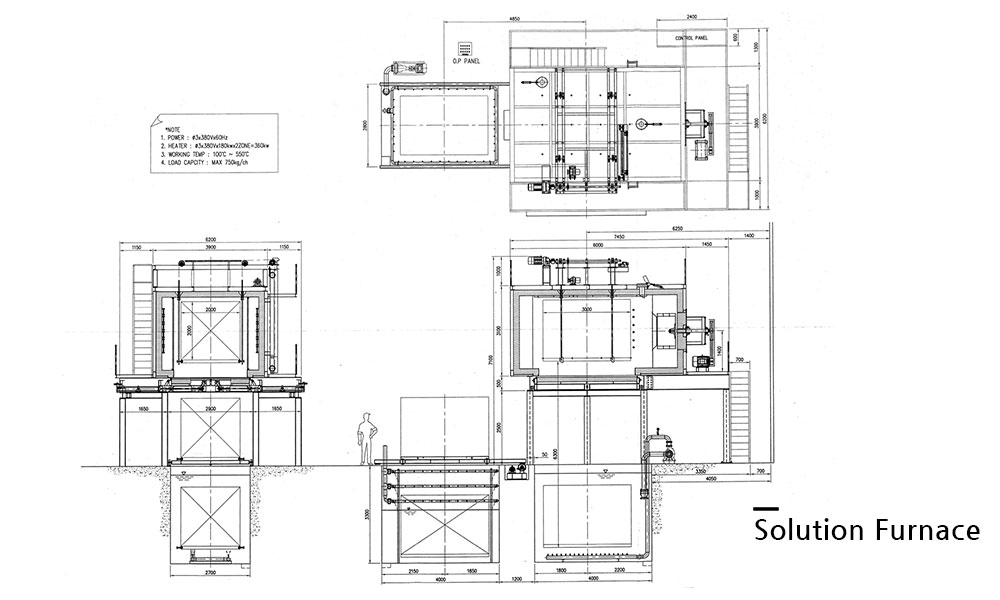

| 5 | Solution Furnance | 2000 | 3000 | 2000 | - | 3900 | 6000 | 3100 | Operating Temperature: 350 ~ 540 ℃ |

| Temperature range: within ± 5.6 ℃ | |||||||||

| RECOVERY TIME : 30min (450kg/CHARGE) | |||||||||

| QUENCHING DELAY TIME : 10, 15, 20 SEC | |||||||||

| QUENCHING MEDIUM : Glycol ( AQUA 260) | |||||||||

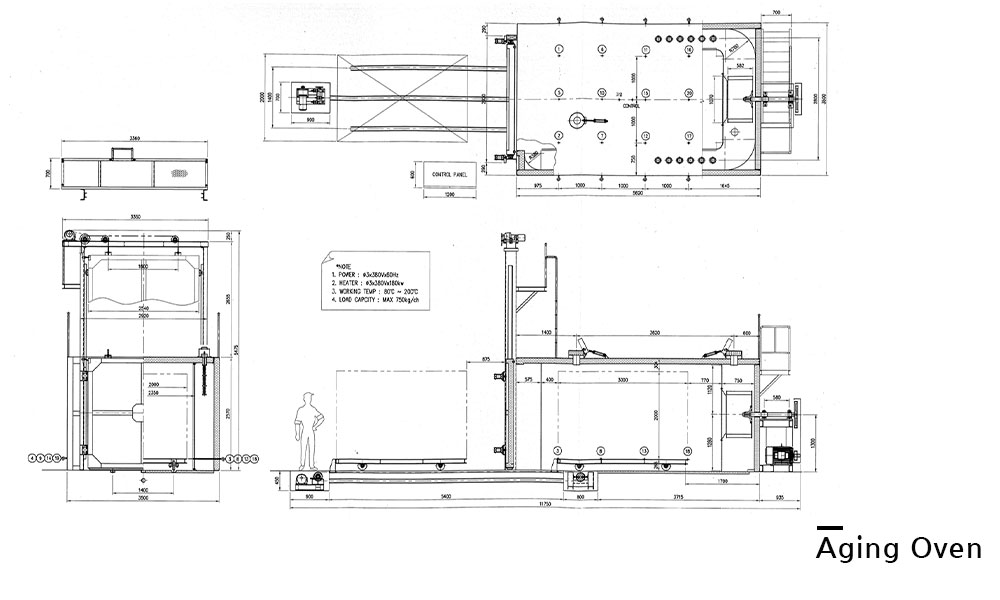

| 6 | Aging Oven | 2000 | 3000 | 2000 | - | 3500 | 5620 | 2570 | Operating Temperature: 90 ℃ ~ 200 ℃ |

| Temperature range: ± 6 ℃ | |||||||||

| HEAT- UP TIME: 40 min (from base, up to 175 ℃) | |||||||||

| 7 | Refrigerator | 3650 | 5000 | 2100 | - | 3950 | 5300 | 2400 | Operating temperature: 0 ~ -27 ℃ |

MOVIE